The Daily Observer London Desk: Reporter- John Furner

Over the past decades, physicists and engineers have been trying to develop various technologies that leverage quantum mechanical effects, including quantum microscopes. These are microscopy tools that can be used to study the properties of quantum particles and quantum states in depth.

Researchers at Silicon Quantum Computing (SQC)/UNSW Sydney and the University of Melbourne recently created a new solid-state quantum microscope that could be used to control and examine the wave functions of atomic qubits in silicon. This microscope, introduced in a paper published in Nature Electronics, was created combining two different techniques, known as ion implantation and atomic precision lithography.

“Qubit device operations often rely on shifting and overlapping the qubit wave functions, which relate to the spatial distribution of the electrons at play, so a comprehensive knowledge of the latter provides a unique insight into building quantum circuits efficiently,” Benoit Voisin and Sven Rogge, two researchers who carried out the study, told Phys.org.

“Spatial information about the wave functions is typically not possible during qubit device measurements as these are based on fixed charge sensing of the whole quantum state. Direct access to the full spatial extent of the quantum state can however be accessed using a scanning tunneling microscope (STM), which we have developed to place atoms in silicon with atomic precision. In this paper we have combined the local control of the wave function used for device operation directly within the microscope.”

The lab at SQC/UNSW Sydney had been previously manufacturing qubit devices and developing scanning tunneling microscopes to image qubit wave functions in parallel, using individual phosphorus atoms embedded in silicon. In their new paper, Voisin, Rogge and their colleagues tried to merge these two different research efforts into a single platform. More specifically, they set out to realize a quantum microscope that could simultaneously map out and control atomic qubits with local electrodes in a single device.

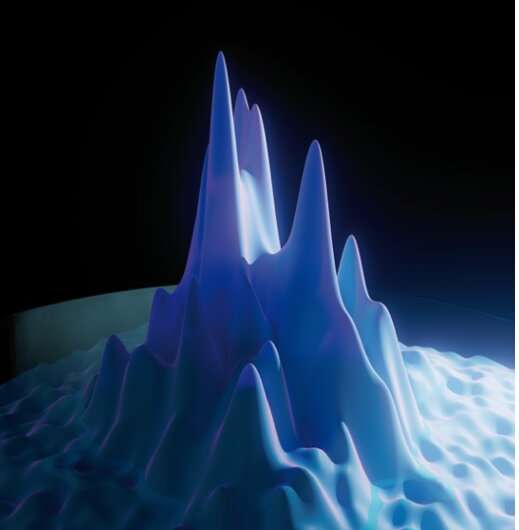

“A quantum microscope is a tool where arrays of atoms can be engineered with atomic precision, and where each atom, or qubit, can be locally controlled and measured,” Voisin and Rogge said. “Comparable microscopes exist in the cold atom community where laser technology is used in a vacuum. Our solid-state version of a quantum microscope very much resembles a transistor, with local electrodes defining the source and gate sides, and the STM tip acting as a drain which can move with picometer resolution from qubit to qubit and scan their wave function.”

The new quantum microscope created by the researchers was created by combining two different techniques. More specifically, they used atomic precision lithography to introduce dopant atoms and more conventional ion implantation techniques to create the electrodes for their device. This unique approach to fabricate quantum microscopes was pioneered at UNSW.

“The qubits are defined using the atomic precision manufacturing technique, by incorporating a few phosphorus atoms in small patches of desorbed hydrogen at the silicon surface, close to the source electrode, Voisin and Rogge explained. “Contrary to typical STM experiments performed on conductive substrates, here our microscope operates on insulating silicon, and we had to design a light-assisted protocol to first stabilize the STM tip before being able to map out the qubit wave functions.”

The researchers’ microscope essentially utilizes the STM tip as a movable electrode, which can have valuable advantages. Most notably, this approach simplifies the collection of large qubit array measurements, without requiring the use of an increasing number of fixed sensors, but instead measuring entire arrays using a single STM tip.

“The ability to map out the qubit wave functions directly during device operation gives us invaluable and predictive insights on how to optimize the device design as we scale, such as distance and orientation between the qubits,” Voisin and Rogge said. “As a consequence, with regard to the manufacturing of complete circuits using the atomic qubits we engineer at our SQC/UNSW lab, our quantum microscope will help speed up manufacturing cycles for better device performance.”

Atomic precision lithography and ion implantation are two distinct processes typically realized in entirely different laboratory conditions. The integration of these two techniques to create a single device was thus a remarkable achievement for the team.

The recent study by Voisin, Rogge and their colleagues could bring a new wave of innovation in the field of STM and quantum microscopy, as it introduces a new approach for fabricating quantum microscopes. In the future, their proposed approach could be applied to microscopes based on other solid-state systems, such as molecules and magnetic atoms.

The SQC lab at UNSW is now exploring two key research directions. Firstly, they are trying to reach beyond the local electrostatic control demonstrated in their recent paper, by performing microwave coherent operations on the qubits inside their microscope.

“To do this, we need sub-100mK temperatures and finite magnetic fields, and we are currently commissioning a new equipment that will provide these capabilities,” Voisin and Rogge added. “The second application we are exploring is to create and probe new correlated states of matter that are challenging to simulate with classical computation techniques or achieve with other experimental platforms such as cold atoms.

“We will fabricate large arrays of qubits strongly coupled to each other, in a regime where topological and superconducting states are expected to emerge. This is a very exciting area where our combination of precision manufacturing and ability to see wave functions directly will open new horizons in our atomic understanding of the world.”